-

400-022-9917

Piston crown reconditioning is a cost effective alternative to the purchase of a new one. Since working under a high-temperature and high-pressure condition for a long time, ring grooves and piston top are very venerable to heat. Its performance will bean be restored in our reconditioning plan.

Before reconditioning  | Corroded piston top  | Corroded piston grooves

|

Equipped with advanced and completemachining equipments, gas shielded arc welding and submerged arc welding machines, large scale tempering heat treatment installation, as well as magnetic particle flaw detector and Ultrasonic Flaw Detector, Mariso is fully qualified to provide reliable piston crown reconditioning service to you with our experience and LR approved working procedures.

|  |  |

Pre-machining to eliminate the corrosion | Dye-check | Dye-check |

|  |  |

Automatic arc-submerging welder | Automatic arc-submerging welding | Final maching CNC verticle lathe |

|  |  |

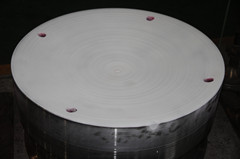

Final machining | Final machining of piston grooves | Piston grooves after machining |

|  | |

After reconditioning LR inspection | ||

- Pre-machining, cleaning damages or cracks and detect the flaws

- Building up cut-off of damages or cracks by welding

- Welding stress relief by heat treatment

- Final machining

- Chrom plating of ring grooves

- Hydraulic pressure test

Pre: None

Next: Cylinder Cover