-

400-022-9917

Echo-Echo Measuring Mode

The Cygnus PLUS + surface thickness gauge models and the

Cygnus DIVE underwater gauge have the option to use them in Echo-Echo mode.

This measuring technique is similar to Multiple Echo as it can be used to read

through coatings without the need to remove them. The maximum coating thickness

that can be measured through and ignored is 1mm. Unlike Multiple Echo though

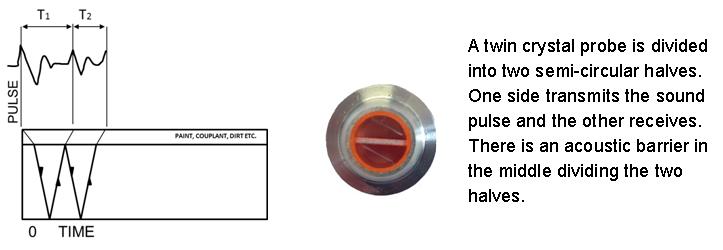

Echo-Echo uses a twin crystal probe.

How it works:

An Ultrasonic Thickness Gauge with a probe uses the time

taken for echoes of sound to travel through a material and converts this into a

thickness measurement.

A short pulse of ultrasound is generated and coupled into

the material from the transmitting side of the probe. The instrument then

listens for back-wall echoes to return to the receiving side of the probe. When

the thickness detects two consecutive echo signals it measures the time between

these echoes and calculates the material thickness. As two consecutive echoes

are used, any thin coating will be automatically ignored. Also because the

gauge is looking for the difference in time between two successive echoes any

V-path error is cancelled out.

MSITM Measurement Stability Indicator

Exclusive to Cygnus, this feature helps ensure only stable measurements are displayed in Echo-Echo mode. If 16 return echoes are the same over a 2 second period the gauge indicates that the reading is stable & therefore highly likely to be accurate.

Advantages of Echo-Echo:

Echo-Echo can be used through coatings up to 1mm thick.

Therefore these coatings do not need to be removed and reapplied. The focussed

"V-path” helps to ensure a strong enough signal gets back the receiving

side of the probe when used on painted metals with heavy back wall corrosion or

pitting.

Next: Single-Echo Measurin...